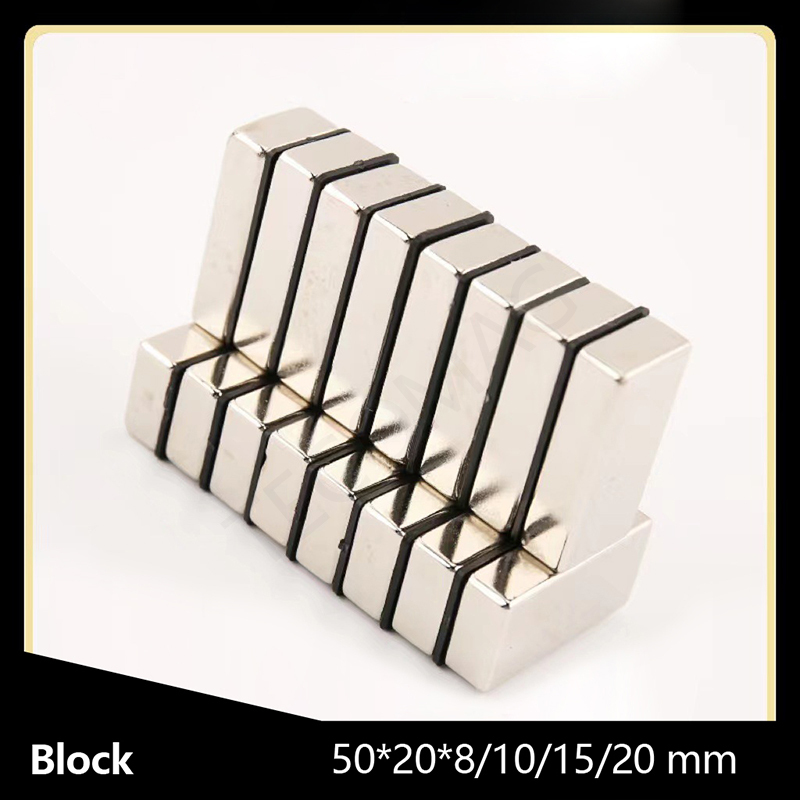

Block Shape NdFeB Magnet

Block Shape NdFeB Magnet Specification

- Application

- Motors, Sensors, Magnetic Separation, Holding, Craft, DIY, Loudspeakers

- Composite

- NdFeB (Neodymium Iron Boron)

- Magnet Grade

- N35, N38, N42, N45, N52 (as per requirement)

- Material

- Neodymium, Iron, Boron Composite

- Surface Finish

- Ni-Cu-Ni (Nickel-Copper-Nickel) plating

- Product Type

- Block Shape Magnet

- Magnet Category

- Rare Earth Magnet

- Magnet Type

- Permanent Magnet

- Shape

- Block / Rectangle

- Size Range

- Customizable; Common: 5mm x 5mm x 2mm to 100mm x 50mm x 20mm

- Weight

- Varies as per size, typically lightweight

- Color

- Metallic Gray / Silver

- Usage & Applications

- Industrial, Educational, Engineering, Home, Electronics

- Capacity

- High magnetic strength; customizable

- Packing

- Standard export packing, individual or bulk

- Coercivity (HcJ)

- 876 kA/m

- MOQ

- Negotiable, based on order size

- ISO Certification

- ISO 9001:2015 Certified production

- Customization

- Size, grade, and coating options available

- Corrosion Resistance

- Good (with protective coating)

- Tolerance

- 0.05 mm or as per customer requirements

- Remanence (Br)

- 1.11.5 T, depending on grade

- Magnetization Direction

- Through thickness or as specified

- Max Working Temperature

- 80C to 220C depending on grade

Block Shape NdFeB Magnet Trade Information

- Minimum Order Quantity

- 1000 Pieces

- FOB Port

- Shenzhen/Shanghai/Ningbo/Qingdao

- Payment Terms

- Paypal, Cash in Advance (CID), Telegraphic Transfer (T/T), Western Union, Letter of Credit at Sight (Sight L/C)

- Supply Ability

- 1000000 Pieces Per Month

- Delivery Time

- 15 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Box / Wooden box

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- ISO9001, IATF16949:2016

About Block Shape NdFeB Magnet

NdFeB Magnet

Material Grade: N35, N38, N40, N42, N45, N48, N50, N52

Coating: Zinc, Nickle, Black Epoxy, Gold, Electrophores,etc

Shape: Segment,Block,Disc,Ring,Rod,Cylinder,Countersunk,etc

Size: OEM/ODM/Customized, flexible to meet your requirements

Features

Diverse shapes and sizes, such as discs, rings, squares, sectors, tiles, irregular shapes, etc.

Powerful magnetic properties

High magnetic energy output

High coercivity

Excellent magnetic stability

Surface coated for protection

Designed for light, thin, short, and small products

Common coatings: nickel-copper-nickel, blue-white zinc, colorful zinc, black epoxy

Operating Temperature

0C240C

Applications:

-

Industrial applications

-

Electric motors and generators

-

Audio equipment

-

Computer hard drives

-

Medical industries

-

Automotive industries

-

Energy, oil, & scientific industries

-

Green Energy

-

Consumer Electronics

Superior Magnetic Performance

Block Shape NdFeB Magnets stand out for their exceptional magnetic strength, durability, and high energy product. These rare earth magnets, made from neodymium, iron, and boron, deliver reliable performance in demanding environments due to their robust coercivity and remanence. Their versatility makes them a favored choice in both industrial and technical settings.

Flexible Customization Options

Customers can request block magnets in sizes from 5x5x2 mm up to 100x50x20 mm, with precise tolerances and a range of available grades. Customizations also extend to different protective coatings and magnetization directions, ensuring compatibility with specific project requirements and optimized performance for tailored applications.

Reliable Protection and Longevity

Finished with a high-quality Ni-Cu-Ni coating, these NdFeB magnets offer excellent corrosion resistance. This surface treatment extends the lifespan of the magnet, even when used in challenging industrial or outdoor environments. Customers can specify other coatings if needed, for enhanced durability in specialized use cases.

FAQs of Block Shape NdFeB Magnet:

Q: How do I choose the right grade and size for my application?

A: You should select the grade (N35N52) and size based on your required magnetic strength, operating temperature, and spatial constraints. Higher grades offer stronger magnetic properties, while temperature requirements may dictate specific grades. Our team can assist you in determining the optimal configuration for your project.Q: What is the process for customizing Block Shape NdFeB Magnets?

A: To customize, simply provide your desired dimensions, grade, coating preference, and magnetization direction. We will work with you to confirm specifications, provide samples if needed, and ensure everything meets your precise requirements before bulk production begins.Q: Where can Block Shape NdFeB Magnets typically be used?

A: These magnets are versatile and widely used in motors, sensors, magnetic separation equipment, holding fixtures, loudspeakers, educational tools, and DIY projects. Their strong performance and adaptability make them suitable for industries such as electronics, engineering, and manufacturing.Q: What benefits does the Ni-Cu-Ni surface finish provide?

A: The triple Ni-Cu-Ni plating enhances the magnets corrosion resistance, preventing degradation from moisture and chemicals, and extending product life. This makes them durable even in aggressive industrial or outdoor settings.Q: When should I choose a custom coating over the standard Ni-Cu-Ni finish?

A: Custom coatings are recommended for highly specialized environments where additional chemical resistance or unique functional properties are needed. If your application involves exposure to extreme conditions, our team can advise on the most suitable surface finish.Q: How is the minimum order quantity (MOQ) determined?

A: The MOQ is flexible and negotiable, depending on your order size and customization requirements. We work to accommodate both small and large batch orders to support various customer needs.

Price 5 INR/ Piece

- Minimum Order Quantity

- 1000 Pieces

- Supply Ability

- 1000000 Pieces Per Month

- Delivery Time

- 15 Days

- Main Domestic Market

- All India

- Main Export Market(s)

- Asia

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sintered NdFeB Magnet Category

Disc Countersunk NdFeB Magnet 40*5*10*20mm

Price 1.5 INR / Piece

Minimum Order Quantity : 10000 Pieces

Magnet Type : NdFeB Magnet

Magnet Category : Permanent Magnets

Color : silver,gold,black,etc

Product Type : Magnets

Disc Countersunk NdFeB Magnet 12*3/4/5mm

Price 1.5 INR / Piece

Minimum Order Quantity : 10000 Pieces

Magnet Type : NdFeB Magnet

Magnet Category : Permanent Magnets

Color : Silver,gold,black,etc

Product Type : Magnets

Cylinder Sintered NdFeB Magnet 4*5/6mm

Price 2 INR / Piece

Minimum Order Quantity : 10000 Pieces

Magnet Type : NdFeB Magnet

Magnet Category : Permanent Magnets

Color : silver,gold,black,etc

Product Type : Magnets

Sintered Neodymium NdFeB Magnet Block With Countersunk Hole

Minimum Order Quantity : 100 Pieces

Magnet Type : NdFeB Magnet

Magnet Category : Permanent Magnets

Color : silver

Product Type : Magnets